The relentless pursuit of energy, especially in today’s volatile global landscape, demands more than just brute force or traditional methods. It requires intelligence, precision, and an unwavering commitment to safety and efficiency. At the heart of this modern energy revolution lies a critical, often unseen, discipline: well control. It’s not merely about preventing blowouts; it’s about exerting intelligent, predictive, and resilient command over the complex dynamics deep beneath the earth’s surface. And leading this charge, particularly in regions like energy europe, is Vertechs, a company whose vision extends far beyond conventional engineering to deliver truly transformative energy engineering solutions.Imagine the immense pressure, the unpredictable geological formations, the sheer complexity involved in managing a well hundreds or even thousands of meters underground. A single misstep can have catastrophic consequences—not just financially, but environmentally and for human lives. This is where

well control becomes the ultimate safeguard, the non-negotiable cornerstone of responsible energy extraction. Vertechs understands that effective well control isn’t just reactive; it’s proactive, integrated, and deeply embedded within a broader, smarter energy control system. Their approach transforms well control from a series of isolated procedures into a dynamic, data-driven ecosystem. Think of it as the central nervous system for the entire drilling operation, constantly monitoring, analyzing, and adjusting to maintain perfect equilibrium. This sophisticated energy control system leverages real-time downhole sensors, advanced AI algorithms, and seamless communication networks to provide operators with unprecedented situational awareness, turning potential disasters into manageable events before they even begin.

vertechs21 發表在 痞客邦 留言(0) 人氣(3)

In the oil and gas industry, the behavior of fluids dictates much of the success in drilling and well construction. Fluid rheology, which is the study of how fluids deform and flow under different conditions, is central to understanding how drilling fluids move, how cement slurries set, and how operations can be optimized to prevent costly downtime or structural failures. When a drilling team prepares to penetrate complex geological formations, the rheological properties of the fluids in the wellbore can make the difference between smooth operations and significant complications.

vertechs21 發表在 痞客邦 留言(0) 人氣(4)

vertechs21 發表在 痞客邦 留言(0) 人氣(4)

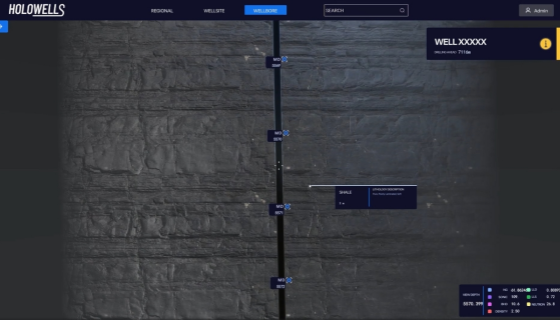

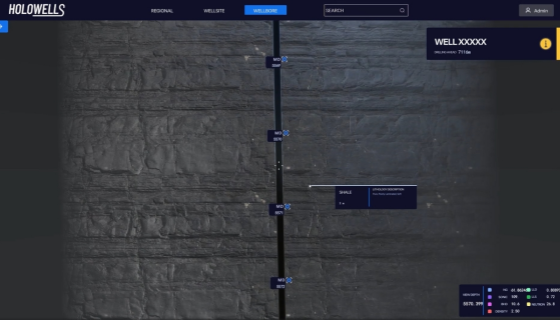

In an era when energy projects are under increasing pressure to be safer, faster, and more cost-effective, Vertechs is quietly redefining what it means to tap into the subsurface. At the heart of their innovation lies a powerful marriage of big data in oil and gas and advanced downhole technology. Rather than relying solely on periodic snapshots or manual sampling, Vertechs builds downhole monitoring systems that feed continuous streams of real-time data from deep inside the wellbore, transforming those subterranean conditions into actionable intelligence.

vertechs21 發表在 痞客邦 留言(0) 人氣(1)

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

In the world of oil and gas, the cementing process plays a pivotal role in ensuring the structural integrity of wells. The science behind this process is intricately linked to fluid rheology, the study of the flow and deformation of fluids. By understanding the principles of fluid rheology, cementing companies can optimize their operations and achieve more effective results. In this article, we explore how fluid rheology is essential in the cementing process and how it relates to various aspects of cementing in the oil and gas industry.

vertechs21 發表在 痞客邦 留言(0) 人氣(3)

When you think of drilling deep into the earth, the image that often comes to mind is a stark cylindrical hole disappearing into rock layers. But in reality, that hole—the wellbore—is a fragile, dynamic boundary between engineering ambition and geological complexity. Its stability is never guaranteed.

Wellbore stability is a constant concern, and it is here that Vertechs steps in, offering a fluid dialogue between chemistry, materials, and digital insights.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

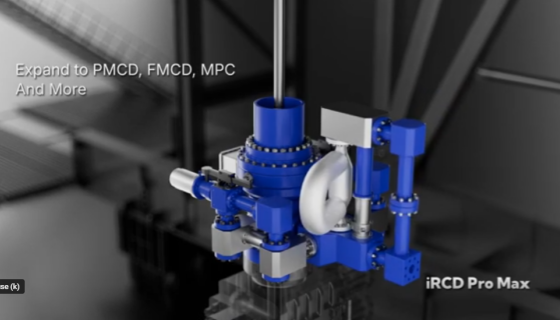

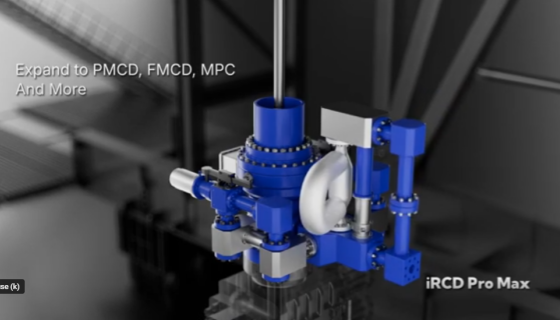

In the oil and gas industry, controlling a well is not just a technical requirement—it’s a matter of safety, efficiency, and sometimes survival. Companies face increasingly complex geological formations, deeper reservoirs, and tighter operational margins, making the role of well control more critical than ever. Vertechs has positioned itself at the forefront of this challenge, offering a blend of innovative well control systems and cutting-edge equipment that empowers operators to manage pressure and flow with precision, while keeping safety as the central priority.

vertechs21 發表在 痞客邦 留言(0) 人氣(3)

In the oil and gas industry, the challenge of loss circulation in drilling remains one of the most critical operational concerns, directly impacting both efficiency and safety. When drilling through complex formations, the unexpected migration of drilling fluids into fractures or porous zones can jeopardize wellbore integrity, compromise drilling performance, and significantly escalate operational costs. Effective management of this phenomenon requires a nuanced understanding of drilling fluid behavior, cutting-edge well tools, and the strategic support of expert well services companies.

vertechs21 發表在 痞客邦 留言(0) 人氣(2)

In the complex world of oil and gas extraction, the role of drilling fluid cannot be overstated. These specialized fluids, often referred to as drilling mud, serve as the lifeblood of the drilling process, maintaining wellbore stability, cooling and lubricating drill bits, and carrying cuttings to the surface. But beyond their traditional roles, modern drilling fluids companies are redefining performance through advanced drilling fluids additives and real-time monitoring technologies. Companies like Vertechs are leading this transformation, offering integrated drilling fluids solutions that combine smart engineering with cutting-edge technology.

vertechs21 發表在 痞客邦 留言(0) 人氣(8)