Chasing the overall wellbeing, we frequently focus on conventional sides like exercise, diet, mental health. However, unfamiliar but equally essential factors contributing to our health is one and only wellbore strengthening. Even nowadays, its impact on our daily personal vitality can be extreme.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

Definition of Frac Plug: It's a Fracturing Plug or downhole tool used in Hydraulic fracturing functions in gas and oil wells. Initially, it can isolate different sections of wellbore during the fracturing procedure. Well, there are several types of Frac plugs are as follows:

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

A dissolvable frac plug is a device used in hydraulic fracturing operations to isolate sections of a wellbore during stimulation. These devices are designed to temporarily block the flow of fluids in the well, allowing pressure to build up behind them so that hydraulic fracturing can occur.

vertechs21 發表在 痞客邦 留言(0) 人氣(1)

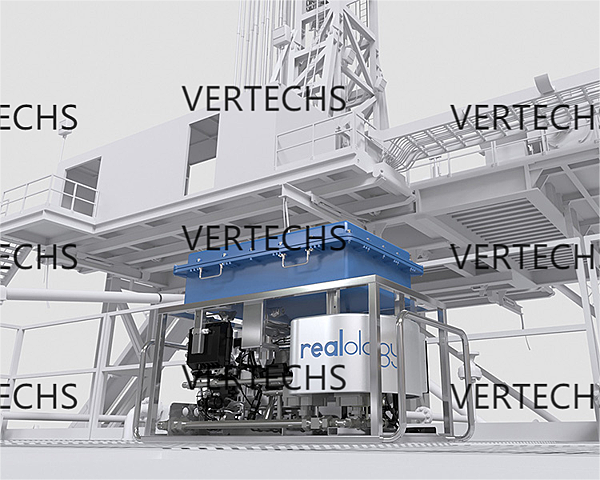

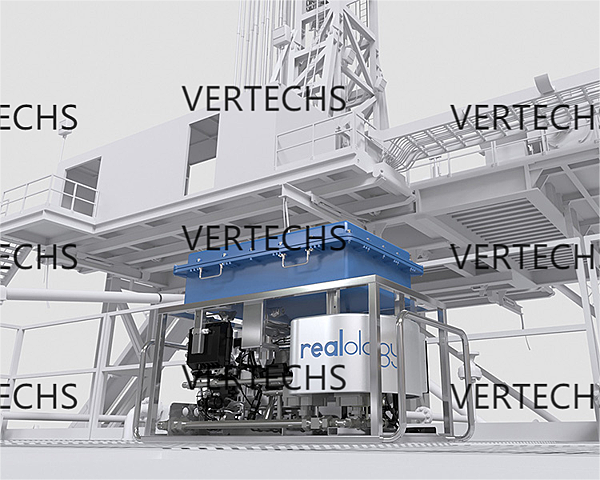

The drilling operations are useful in obtaining valuable resources of the earth in the changing oil and gas industry. As drilling technology is expanding brands like Vertechs come to the forefront. They are giving cutting-edge goods and services to boost productivity and environmental responsibility.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

Drilling operations are important in obtaining the valuable resources of the earth in a fast-paced world with a constantly changing oil and gas industry. As drilling technology develops we should be able to provide cutting-edge goods and services to boost productivity, safety, and environmental responsibility. Managed pressure Drilling also known as MPD is one such innovative method that has gained popularity in recent times.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

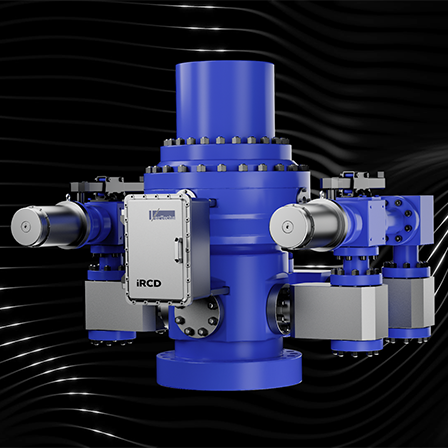

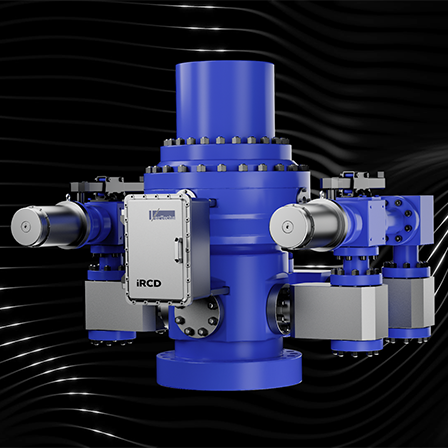

Exploring the pioneering technology that contributes to the sustainable practices for drilling operations globally. Gain your awareness into Fluid Intelligence and how it can revolutionize the gas and oil industry.Definition:Fluid Drilling states the use of drilling fluids, like mud, in the procedure of drilling gas and oil wells. The purpose of these fluids offers cooling the drill bit, shifting cuttings to the surface, and giving stability to the wellbore. Evolution of Drilling Fluids: Evolution is all about continuous advancements to address the threatful circumstances in drilling operations, here’s a brief insight:Water-based Mud (WBM): At the beginning, water-based mud was commonly used and it was lucrative in nature. It contains clay, water and other additives. It provides stability and performance.Oil-based Mud (OBM): To avoid the limitations of water-based mud, oil-based mud was introduced. It provides better lubrication, stability as well as possessing environmental concern whereas suitable for any drilling challenges. It can be more expensive than WBM. Synthetic-based Mud (SBM): These Synthetic-based mud extract from Synthetic oil, was developed to merge the advantages of both WBM and OBM. The major features consist of thermal stability, improved performance, and environment friendly.High-Performance Water-Based Mud: Its advances in chemistry guiding the development of High performance water-based mud, providing stability and performance enhancement with reducing environment clashes.Invert Emulsion Mud: This method states that the use of water droplets sprinkle on oil, providing wellbore stability and cutting encapsulation that differentiate from conventional oil-based mud method. Nanotechnology: These technologies increase the properties like lubricity, stability and Filtration control. Researchers prospecting assimilate nanoparticles into drilling fluids for better enhancement.Eco-friendly Fluids: The initial focus of advanced drilling fluids that are biodegradable and less foe to the environment. Managed Pressure Drilling (MPD): It is a progressive drilling technique that involves controlling active wellbore pressure in the course of drilling operations. The procedure is complete by fixing the density of drilling fluid or using the rotation control device. It helps in improving safety and better efficiency.Principle of MPD drilling:The initial goal of managed pressure drilling is to improve drilling efficiency, enhance safety and empower drilling for a challenging environment and running the pressure in the wellbore all over the drilling operations. Now, Let’s hook into the key concept involved:

Exploring the pioneering technology that contributes to the sustainable practices for drilling operations globally. Gain your awareness into Fluid Intelligence and how it can revolutionize the gas and oil industry.Definition:Fluid Drilling states the use of drilling fluids, like mud, in the procedure of drilling gas and oil wells. The purpose of these fluids offers cooling the drill bit, shifting cuttings to the surface, and giving stability to the wellbore. Evolution of Drilling Fluids: Evolution is all about continuous advancements to address the threatful circumstances in drilling operations, here’s a brief insight:Water-based Mud (WBM): At the beginning, water-based mud was commonly used and it was lucrative in nature. It contains clay, water and other additives. It provides stability and performance.Oil-based Mud (OBM): To avoid the limitations of water-based mud, oil-based mud was introduced. It provides better lubrication, stability as well as possessing environmental concern whereas suitable for any drilling challenges. It can be more expensive than WBM. Synthetic-based Mud (SBM): These Synthetic-based mud extract from Synthetic oil, was developed to merge the advantages of both WBM and OBM. The major features consist of thermal stability, improved performance, and environment friendly.High-Performance Water-Based Mud: Its advances in chemistry guiding the development of High performance water-based mud, providing stability and performance enhancement with reducing environment clashes.Invert Emulsion Mud: This method states that the use of water droplets sprinkle on oil, providing wellbore stability and cutting encapsulation that differentiate from conventional oil-based mud method. Nanotechnology: These technologies increase the properties like lubricity, stability and Filtration control. Researchers prospecting assimilate nanoparticles into drilling fluids for better enhancement.Eco-friendly Fluids: The initial focus of advanced drilling fluids that are biodegradable and less foe to the environment. Managed Pressure Drilling (MPD): It is a progressive drilling technique that involves controlling active wellbore pressure in the course of drilling operations. The procedure is complete by fixing the density of drilling fluid or using the rotation control device. It helps in improving safety and better efficiency.Principle of MPD drilling:The initial goal of managed pressure drilling is to improve drilling efficiency, enhance safety and empower drilling for a challenging environment and running the pressure in the wellbore all over the drilling operations. Now, Let’s hook into the key concept involved:vertechs21 發表在 痞客邦 留言(0) 人氣(1)

In the vigorous monarchy of gas and oil exploration, innovation is the key to reducing risks and improving efficiency. The groundbreaking approach is Managed pressure drilling coupled with an ultra-modern Fluid Monitoring System. In this comprehensive guide, we understand the difficulties of these systems, inspect their introduction, key elements, benefits and metamorphosis impact on drilling operations.Introduction Managed Pressure Drilling (MPD):Managed pressure drilling is an extensive technique that allows precise control over the wellbore pressure, and is a safer and highly efficient alternative to conventional drilling methods. In contrast to traditional drilling, MPD actively copes and adjusts the wellbore pressure throughout the operation. This adaptability offers optimal well control, minimizing the feasibility of losses, kicks and other drilling disputes.Key Elements of MPD:Sustained Monitoring Systems: Real-time data collection is predominant in mpd drilling. The major benefits from sensors and monitoring devices simultaneously gather information on pressure, flow rates and other analytical parameters.

In the vigorous monarchy of gas and oil exploration, innovation is the key to reducing risks and improving efficiency. The groundbreaking approach is Managed pressure drilling coupled with an ultra-modern Fluid Monitoring System. In this comprehensive guide, we understand the difficulties of these systems, inspect their introduction, key elements, benefits and metamorphosis impact on drilling operations.Introduction Managed Pressure Drilling (MPD):Managed pressure drilling is an extensive technique that allows precise control over the wellbore pressure, and is a safer and highly efficient alternative to conventional drilling methods. In contrast to traditional drilling, MPD actively copes and adjusts the wellbore pressure throughout the operation. This adaptability offers optimal well control, minimizing the feasibility of losses, kicks and other drilling disputes.Key Elements of MPD:Sustained Monitoring Systems: Real-time data collection is predominant in mpd drilling. The major benefits from sensors and monitoring devices simultaneously gather information on pressure, flow rates and other analytical parameters.vertechs21 發表在 痞客邦 留言(0) 人氣(0)

In the pursuit of sustainable energy solutions, the gas and oil industry find itself at a junction. As energy demand rises globally, the crucial characteristics to balance this growth with environmental responsibility has never been more grave. Vertechs enter into the market revealing major game-changer possibilities for future sustainability. Introducing Managed Pressure Drilling (MPD) and Wellbore strengthening provides energy potential or efficiency and declining environment collisions.

The Importance of Sustainable Energy Solutions:

The traditional solutions of oil and gas extraction have been connected with environmental challenges. As different communities demand cleaner and more ecological energy sources, because it's our need to possess a healthy environment. You heard about oil spills that disrupt the habitat afterwards no outcome is up to the mark. But the problem is declining because of managed pressure drilling and wellbore strengthening solutions.

Managed Pressure Drilling: Transforming process

Managed Pressure Drilling is a progressive technique that improves the whole drilling process, enhancing the efficiency as well as safety from a non-polluting environment. Generally, conventional methods of MPD optimize for real-time control and supervision of wellbore pressure. It helps in drilling parameters and minimizes the risk of blowouts and kicks.

The increased recovery of hydrocarbons with respect to ensuring a safer drilling environment leads to maintaining an equilibrium in the wellbore pressure. This process exhibits lower cost, reduced drilling time, and a very important declining environmental impact.

Environmental Features: MPD Drilling

● Water Conservation:The disruptions from oil and gas happen unknowingly, the only natural resource we need the most is water. As the conventional drilling methods require excessive water to slow down the processes. MPD drilling efficiency in reducing drilling time contributes to conserving water directly. In Fact, due to excessive use of water, most regions are facing difficulty from water scarcity.

● Preserving Habitat: As MPD drilling minimizes the footprints of drilling operations, this possesses less disturbance to the ecosystem and habitat surrounding drilling sites, a shield for biodiversity.

● Minimise Flame: MPD drilling is made by focusing on flame or flare, it facilitates better control over the well. While flaring releases harmful gases like greenhouse gas that pollute the atmosphere and transform the climate. MPD addresses the ecological concern at the time of curbing flaring directly.

Wellbore Strengthening: Increase Durability and Safety

The wellbore strengthening addresses the dispute and the challenges connected with wellbore instability. The conventional methods possess wellbore collapse and other stability matters, at end with increased costs and biodiversity detroit. But nowadays, wellbore strengthening has become most important in the drilling process which leads to challenging geological formations.

Environmental features: Wellbore Strengthening

● Preventing Formation damage: Wellbore Strengthening accessories prevent surrounding geological formation damage. It helps to increase the life of a well, establishing a sustainable drilling process.

● Lower Environmental Remediation: the prevention of wellbore instability showcase hardly examples of environmental remediation. It changes to lower costs and diminishes the impact on biodiversity.

Conclusion: A Greener compass

The opening of many possibilities by adoption of Managed Pressure Drilling and Wellbore Strengthening represents a chief step towards a more sustainable future for the gas and oil industry. With the environmental benefits, enhances operational efficiency, make these technologies requisite for life.

As Collaborator, we have a responsibility to recommend for investing in life-changing solutions that give us growing energy demands with respect to ensuring a harmonious synchrony with our planet. As saving earth is our primary footsteps. Using the Managed Pressure Drilling and Wellbore Strengtheningguiding us towards a greener compass or horizon where environmental preservation and energy extraction is predominant. Nowadays, companies align with global sustainable goals as well as gaining competitive margin through cost-effectiveness and efficiency of operations.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

In the fast-paced world of oil and gas exploration, Managed Pressure Drilling (MPD) has emerged as a pioneering technique, promising unprecedented precision and control. However, as with any innovation, navigating the challenges that come with implementation is crucial. This exploration delves into the intricacies of MPD, spotlighting the hurdles faced and the role of cutting-edge drilling fluid solutions in overcoming them.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)

In the ever-evolving landscape of drilling technologies, two methods stand out:

MPD drilling and conventional drilling. Each approach comes with its own set of advantages and disadvantages, influencing the choice made by drilling professionals. In this blog post, we'll dive into the comparison of

MPD drilling with traditional methods, shedding light on the pros and cons associated with each.

vertechs21 發表在 痞客邦 留言(0) 人氣(0)